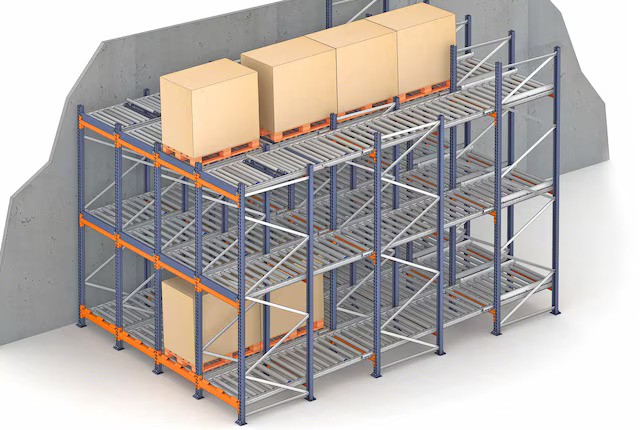

Pallet Flow Racking

Pallet flow racking is a high-density storage solution designed for streamlined operations and efficient inventory management. It features slightly sloped channels with rollers that allow pallets to slide into position using gravity. Palletized loads are placed at the highest point of the channel and naturally move to the opposite end, ready for retrieval.

This system eliminates the need for intermediate aisles, significantly increasing storage capacity. Ideal for FIFO (first in, first out) inventory strategies, pallet flow racking ensures smooth stock rotation and improved operational efficiency.

Advantages:

- Optimized Space Utilization: High-density design significantly increases warehouse capacity by maximizing surface area.

- Efficient Product Turnover: Fully compatible with the FIFO method, ensuring precise inventory control and seamless stock rotation.

- Time Savings: All SKUs are accessible from a single working aisle, reducing forklift maneuvering time and speeding up pallet retrieval.

- Separate Loading and Unloading: Distinct aisles for storage and retrieval eliminate interference, allowing forklifts to operate without interruptions.

- SKU Variety: Each channel holds a single SKU, but multiple SKUs can be stored across different channels for flexibility.

- Energy Efficiency: Ideal for cold storage, as its compact design reduces the volume to be cooled, cutting energy consumption.

- Safety and Reliability: Built with robust components to ensure risk-free operation, protecting both operators and stored goods.

Pallet flow racking delivers space efficiency, streamlined workflows, and dependable performance for warehouses requiring high-density storage with excellent inventory turnover.