Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are innovative devices that carry out tasks and navigate warehouses autonomously, without human intervention. These robots are designed to streamline operations, offering independent movement and precise task execution.

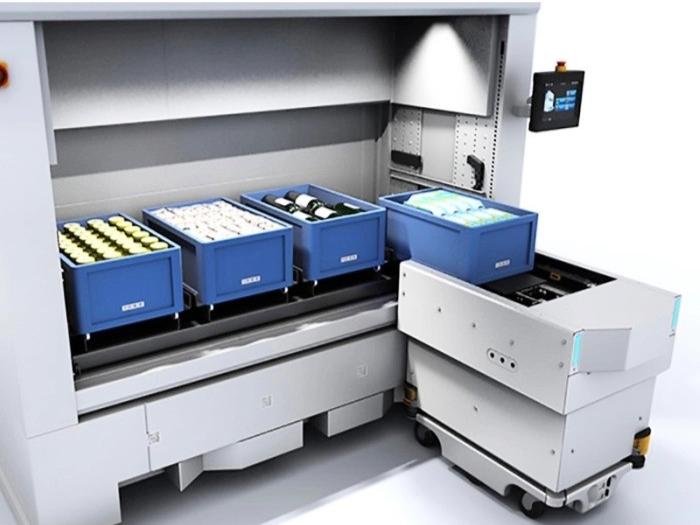

Modula has partnered with MIR (Mobile Industrial Robots), a leader in logistics-focused AMRs. These agile robots are equipped with advanced sensors, AI-powered software, and digital mapping to navigate warehouse spaces efficiently and accurately.

By integrating AMRs with Modula solutions, your warehouse transforms into a fully automated system, where the robots and warehouse operations work in harmony to ensure seamless efficiency. The result is a fully coordinated environment that operates autonomously, with minimal human input.

What does integrating AMR and Modula mean for you?

Reduced Errors and Increased Productivity AMRs enhance operational efficiency by working continuously and around the clock. They follow pre-programmed routes, avoid obstacles, and minimize downtime, making processes faster and more reliable.

Enhanced Workplace Safety AMRs are capable of operating in challenging conditions such as hazardous, dark, or cramped areas where human workers might face safety risks. Their advanced safety features ensure they stop instantly when encountering obstacles, even unexpected ones, greatly reducing the chances of accidents. This technology is the outcome of extensive development to create safe and effective AMR systems for industrial use.

How Mobile Robots Transport Materials

Autonomous Mobile Robots (AMRs) are utilized in innovative ways to transport materials, either retrieved from Modula automatic warehouses or other storage systems. These robots can carry materials autonomously across the facility, streamlining logistics and improving operational efficiency.

Manual Picking In manual picking, a human operator retrieves items from the Modula tray and hands them off to the AMR, or replenishes the Modula tray with materials delivered by the robot. This process relies on human intervention to load or unload the robot.

Automatic Picking In automatic picking, the robot performs the entire picking process. Equipped with a customizable “top module” that adapts to the material’s weight and type, the robot can autonomously approach a Modula warehouse, pick up trays of materials, and place them in the designated location, all without human involvement.

Pallet Transportation AMRs are also capable of transporting pallets. The robots can pick up or deposit pallets and then move them throughout the warehouse, reducing the need for manual labor in material handling.

Hook and Picking Cart For high-volume order fulfillment, a mobile put-to-light system like the picking cart is useful. The picking cart, which can be moved either manually or automatically, is equipped with a tow hook as part of its "top module." This allows the cart to be transported autonomously, facilitating fast and efficient order processing.