Modula Green

Modula Green is an energy-saving solution designed to enhance the already low consumption of Modula warehouses, which operate at less than 1.2 kWh. This option recovers energy generated during the descent phase of the lift and reuses it during the ascent phase, reducing energy waste and improving efficiency.

At the core of Modula Green is a specialized inverter, installed between the main switch and the machine's electrical panel. This inverter acts as an energy stabilizer during the lift phase and as a generator during descent. The recovered energy is fed back into the customer’s network, reducing overall power consumption.

By converting the energy from the elevator’s descent, which would otherwise dissipate as heat, Modula Green leverages advanced DC-BUS technology to create a more sustainable and cost-effective warehouse operation. This innovative feature aligns with eco-friendly practices while delivering tangible energy savings.

ESD Protection

The ESD protection system safeguards operators and stored items by preventing harmful electrostatic discharges. This system is essential for handling sensitive materials such as electronics, gases, fuels, or explosives, where static discharges can pose serious risks.

Electrostatic charges can transfer when a human body contacts an object with a different potential, sometimes resulting in visible or invisible sparks. To mitigate these risks, the Modula automatic warehouse is equipped with an ESD protection system that neutralizes static energy before it can cause harm.

Key components of the ESD system include:

- A grounding point with a total resistance of 1 MΩ

- Up to three operator wristbands

- An optional antistatic mat

The system also features special tray contacts connected to the grounding point. When a tray exits the machine, it touches these contacts, neutralizing any electrostatic charge before it reaches the operator.

This setup ensures a safer working environment and protects sensitive materials from damage caused by electrostatic discharges.

Zero °C Device

The Zero °C device enables Modula machines to operate efficiently in environments where temperatures drop to 0 °C.

This system includes a heating mechanism for the control cabinet, featuring a heating cable and a support plate. The heating system activates automatically as needed, ensuring the machine operates seamlessly, even in colder conditions.

How it works:

- The device heats the electrical cabinet, maintaining optimal operating temperatures for the machine at 0 °C.

- Located inside the cabinet, it operates using specialized electrical components included with the system.

Note: The Zero °C device must be installed during the initial setup of the machine. It’s an essential option for facilities operating in cold environments, ensuring reliable performance and protection of the machine’s electrical components.

Remote Electrical and Transformer Panel

The transformer panel is designed to adapt the mains voltage to suit the Modula machine's requirements. Depending on the model, it can transform:

- From 208 to 400 Vac (3PH)

- From 575 to 400 Vac (3PH)

- From 110 to 230 Vac (1PH)

This panel can also be installed remotely, allowing it to be located separately from the machine base.

Installation Requirements:

- The panel must be positioned outside the machine for accessibility during inspections or maintenance.

- Electrical conductors must be shielded with protective sheaths.

- If installed in areas with vehicle traffic, conductors should be embedded in foundations or driveways to ensure safety and durability.

This flexibility in placement ensures easier access and compatibility with various facility layouts.

Single-Phase Power Supply

The single-phase power supply unit transforms a 230 Vac single-phase mains supply into 575 Vdc and 440 Vac outputs.

Key Features:

- Enables machine operation in facilities without a 400 Vac three-phase power supply.

- Designed for seamless integration during the machine's installation process.

Important Note:

This accessory must be installed at the same time as the machine and cannot be added later.

The single-phase power supply ensures flexibility for installation in diverse electrical environments.

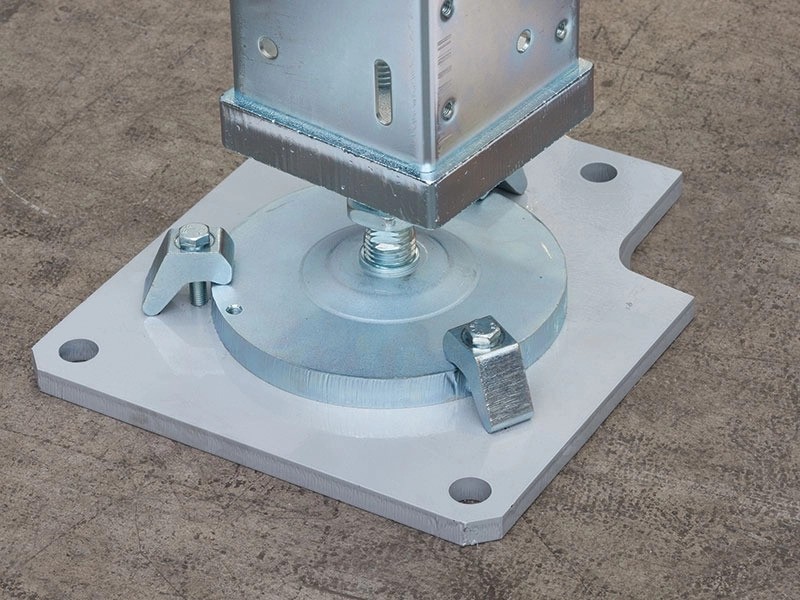

Weight Distribution Plates and Oversized Feet

Weight distribution plates and oversized feet are designed to provide additional support for Modula machines, particularly in cases where the floor does not meet required load-bearing standards.

Modula Lift:

Weight distribution plates are installed to ensure stability, especially for configurations with:

- Single tray capacities of 750 kg or 990 kg.

- Two sets of bays positioned on the same side.

Modula Slim:

Oversized feet are used to evenly disperse the load across a larger surface area, minimizing pressure on specific points.

These solutions enhance safety and ensure the machines operate reliably on various flooring types.

Sprinkler Predisposition

The Modula machine enclosures can be equipped with a predisposition for installing sprinklers, enabling targeted water discharge in case of a fire.

Pre-cut openings are made to accommodate sprinklers, tailored to the customer's specified dimensions. The installation and supply of sprinklers remain the customer’s responsibility.

Perforated Panels for Ventilated Machines

Perforated panels are designed to support air circulation within vertical storage systems, maintaining the quality of stored items. These panels are especially valuable for businesses in the food and beverage industry that require proper ventilation to store fresh products effectively.

Key Benefits:

- Enhanced Air Circulation: Helps preserve the integrity of temperature-sensitive goods.

- Industry-Specific Use: Ideal for sectors needing ventilation for fresh product storage.

- Flexible Implementation: Compatible with all Lift range models that have a minimum height of 3 meters.

This option ensures efficient and safe storage while meeting the specific needs of ventilated warehousing.