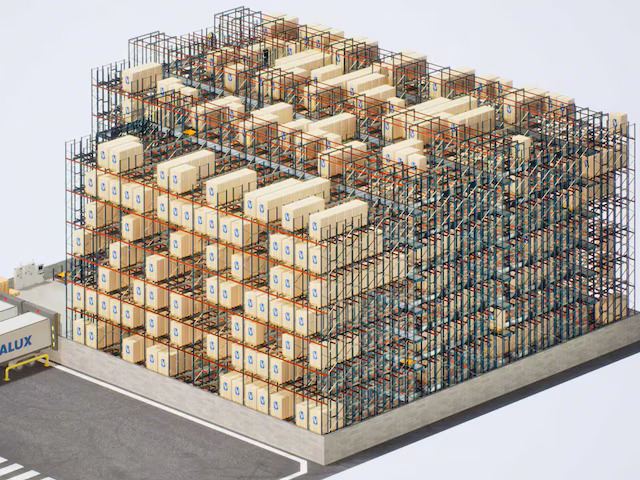

The 3D Automated Pallet Shuttle from Mecalux is a next-generation high-density storage solution that utilizes an innovative multi-directional electric shuttle. This autonomous shuttle car efficiently stores and retrieves pallets from racking with exceptional precision. It navigates aisles and channels independently within the racking structure, eliminating the need for additional material handling vehicles, such as stacker cranes or transfer cars. The shuttle uses a series of lifts to move between storage levels.

As a cutting-edge Automated Storage and Retrieval System (AS/RS), the 3D Automated Pallet Shuttle increases warehouse productivity, maximizes space utilization, and significantly boosts storage capacity. Its extraordinary versatility allows businesses to adapt to dynamic scenarios like demand peaks or high-priority tasks. Additionally, its modular design enables easy scalability, allowing the AS/RS to grow and meet future capacity and throughput needs.

Advantages:

- High Productivity: The rapid navigation speed and operational versatility of the multi-directional 3D shuttles significantly enhance warehouse performance, reducing cycle times and increasing throughput.

- Maximum Flexibility: The shuttle cars move seamlessly between levels and aisles. Additionally, multiple shuttles can operate in a single aisle simultaneously, allowing managers to adapt the system’s throughput to evolving needs, such as priority tasks and demand peaks.

- Greater Capacity and Diversification: Compact storage maximizes space efficiency, increasing warehouse capacity. The system accommodates multiple SKUs and pallet sizes within each channel, offering greater storage flexibility.

- Autonomous, Smart Operation: The shuttles operate autonomously, navigating aisles and channels without requiring other material handling vehicles. Mecalux’s fleet management software ensures smooth shuttle traffic, preventing jams and avoiding collisions.

- Operational Efficiency and Agility: Equipped with sensors for safe and efficient pallet handling, the shuttles ensure precise positioning. The design of the wheels and rails ensures smooth, stable movement and effortless directional changes.

- Scalability: The modular design of the system allows for easy expansion to accommodate future business growth. New shuttles, aisles, and levels can be added to increase capacity and productivity.

- Wide Temperature Range: The shuttles are capable of operating in low temperatures, making them ideal for cold-storage and freezer environments. High-density storage in such facilities leads to significant energy cost savings.

- Comprehensive Solution: Mecalux provides a complete AS/RS solution, including the design, manufacture, installation, and commissioning of all components—shuttles, lifts, racking, conveyors, fleet management software, and warehouse management systems (WMS).